Clipex Fencing

Clipex® is the multi-award winning innovative galvanised steel post.

-

Each post has pre-fixed clips designed to take all the horizontal wires of your chosen wire netting.

-

Each wire is held firmly in place with a spring-loaded clip, no fiddly parts to lose or fit after erection. These clips allow lateral flex, but very little vertical wire movement can happen, which is important when livestock start putting pressure on the fence.

-

Each post has a pre-fixed anti-lift plate below ground level to prevent lifting in soft or undulating ground.

-

Hot dip galvanised and independently tested in the UK, exceeding British Standard coating recommendations.

Clipex Posts

Triple X

Triple X Strainers have been designed by McVeigh Parker and are proven in the field throughout the UK. Used by contractors, utility companies, farmers and landowners for stock, deer and security fencing. Their British made strainers are a very good alternative to more traditional timber strainers, lasting much longer and saving significant installation and labour time. When teamed up with the Clipex® posts and their premium quality X Fence alu/zinc wire netting, you'll have a fencing system that has a life expectancy of over thirty years.

Wire

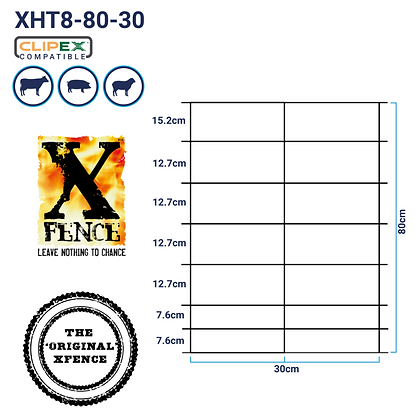

Clipex Compatible Wire

An unobtrusive smooth surface X knot greatly reduces the risk of fleece removal or hide damage, this is the most common mesh pattern used in the UK, ideal for most types of livestock.

BENEFITS

• Superior alu/zinc coated wire, lasts 3-4 longer than galvanised wire

• 450mm pre-stripped ends more than most

• Premium primary wires only used in Xfence fabricated netting

• Consistent superior high tensile strength wires only

• Greater rigidity due to the one-piece vertical wires

• Smoother and safer non-abrasive forged X knot

• Proven in the field since its conception in 2007

• Easier to install, almost self-supporting

• Save on both labour and posts

• Longer maintenance free life

• Guaranteed to last

• Made in New Zealand by the specialists in high tensile fencing

• 24% stronger Knot

• Manufactured to BS EN 10223-5

• Exceeds BS EN 10244 Class A

• Wire produced to BS 4102